The 21st century sees an intricate dance of science, engineering, and human ingenuity. Amidst this dance, SpaceX's Starship stands tall, aiming to conquer the Red Planet. As we witness the momentous Starship launch test last month, the question that lingers is not whether we will reach Mars. Instead, we ponder the age-old principle, how will we ensure that what goes up, indeed, comes down safely?

SpaceX's Starship and the Challenges of Reentry

SpaceX's pride, the Starship, is at the heart of the endeavor to conquer Mars. This state-of-the-art spacecraft is the product of numerous iterations and relentless testing, a testament to the rigorous pursuit of innovation. Starship is more than just another rocket, it's a beacon of human determination and the embodiment of Elon Musk's audacious vision to make life multi-planetary.

But dreams are not realized without overcoming hurdles, and Starship is no exception. One of the most formidable challenges it faces is surviving the fiery reentry into Earth's atmosphere. Picture this: Starship, a gleaming tower of stainless steel, hurtling back to Earth at a blistering speed of at least 7.8 kilometers per second (Mach 23 or 17,500 miles per hour). The process of decelerating from orbital velocity to a standstill involves converting a substantial amount of kinetic energy into heat. And that heat, if not managed correctly, can spell disaster.

Enter heat shields, the unsung heroes of space travel. These robust devices are designed to absorb and dissipate the intense heat generated during reentry, essentially preventing spacecraft from turning into celestial fireballs.

The Composition and Design of Starship & Heat Shield

SpaceX chose stainless steel as the primary material for Starship's construction, a decision that may seem counterintuitive when you consider the lightweight materials commonly used in aerospace. However, the choice of stainless steel, with its ability to withstand temperatures up to 1600 degrees Fahrenheit, is part of a complex equation involving weight, strength, and temperature resistance.

The crux of Starship's heat management strategy lies in its heat shield technology. SpaceX has been developing, testing, and refining this technology for over four years, with a particular focus on the heat shield tiles. These hexagonal tiles, each possibly containing a substantial amount of silica, serve as the first line of defense against the searing heat of reentry. The hexagonal design is no accident, this shape prevents hot gas from accelerating through the gaps and enhances tile stability during reentry.

To grasp the magnitude of the challenge, consider this: Starship's reentry profile is strikingly similar to that of NASA's retired space shuttle. This process takes approximately 20 minutes from orbit to touchdown. But unlike the space shuttle, Starship is designed for rapid reusability, a feature that hinges heavily on the performance and durability of its heat shields.

The Use and Challenges of Ceramic Tiles

Choosing ceramic for the thermal protection tiles was a strategic decision. Ceramic tiles offer the benefit of rapid reuse, a key requirement for SpaceX's vision of frequent, cost-effective space travel. But these advantages come with their own set of challenges. Ceramic tiles are fragile and prone to shattering or falling off, a problem that has been painfully evident during testing. Moreover, producing these tiles is a time-consuming process. Each Starship requires approximately 25,000 of them, each one requiring careful manufacture and inspection.

The Attachment and Maintenance of Heat Tiles

Interestingly, the tiles on Starship aren't glued to the spacecraft's exterior but are attached using studs. This unique method significantly reduces maintenance time, making replacing and refurbishing the tiles easier, an essential feature for a spacecraft intended for multiple flights.

Another critical component in the tile attachment process is Kaowool 3000, a white flexible ceramic fiber mat. Positioned between the back of the tile and the stainless steel body of Starship, this material improves tile attachment and contributes to the overall heat resistance capability of the spacecraft.

Overall, Starship's design seems to offer significant advantages over the space shuttle, notably in terms of safety and cost-effectiveness. The space shuttle was more dangerous and expensive compared to traditional crew capsules and similarly capable expendable rockets. With its reusable design and sophisticated heat shield technology, Starship could revolutionize the future of space exploration.

The Advancements in Heat Shield Technology

To truly comprehend the enormity of SpaceX's ambitions with Starship, one needs to appreciate the significance of its thermal protection system. It's not just about surviving the reentry, it's about doing it over and over again, with minimal downtime for refurbishment. In essence, Starship aims to bring the convenience of commercial airliners to space travel, and an effective and robust thermal protection system plays a critical role in realizing this vision.

SpaceX isn't new to the game of heat shields. Its Dragon capsule, designed for ferrying astronauts to and from the International Space Station, uses a heat shield known as PICA-X. However, this ablative heat shield, which wears away to dissipate heat, doesn't meet Starship's need for rapid reusability.

Starship, instead, employs a different approach to overcoming the heat shield challenges that plagued the Space Shuttle, which suffered from foam and ice debris falling onto the shield during launch. Thanks to its simpler geometry and unique mounting system, Starship effectively circumvents these issues.

A key aspect of Starship's heat shield design is the use of hexagonal tiles. These identical tiles not only simplify production but also offer a high degree of flexibility and respond well to structural movement. Between these tiles and Starship's stainless steel body is a ceramic wool pad, which, while not a primary heat shield, serves to improve tile attachment.

Challenges and Solutions in Heat Shield Design

With its towering stature and intricate architecture, Starship presents unique challenges in a heat shield design. Areas like the tapering nose cone and the uniquely shaped fins require multiple strategies to accommodate the curvature. However, the SpaceX team has been industriously filling these complex structures with tiles, demonstrating the flexibility of their design approach.

Starship 20 nose cone getting covered with thermal insulation right now.

— Starship Gazer (@StarshipGazer) July 28, 2021

2:15 pm 7/28/21 pic.twitter.com/TWbs1VpUYo

While unconventional, the choice of stainless steel material for Starship's construction offers several advantages. Its reflective properties help deflect heat, much like the white upper surface of the Space Shuttle. In contrast, the black bottom surface is specifically designed for efficient heat radiation, providing a balance of reflection and emission.

Transpiration cooling, a concept that Elon Musk has previously mentioned, also deserves a brief mention here. Though its application in Starship isn't yet confirmed, this method, which involves pumping coolant through tiny pores in the heat shield, could provide an additional layer of heat management in future iterations.

Innovations and Experiments

The solution to the tile problem might lie in the very structure of Starship itself. Its thin steel propellant tanks serve as the base for the heat shield, a design choice that's as daring as it is risky. The vibrations during engine firing on the test stand are much stronger than those experienced during the actual flight, necessitating a robust tile attachment method.

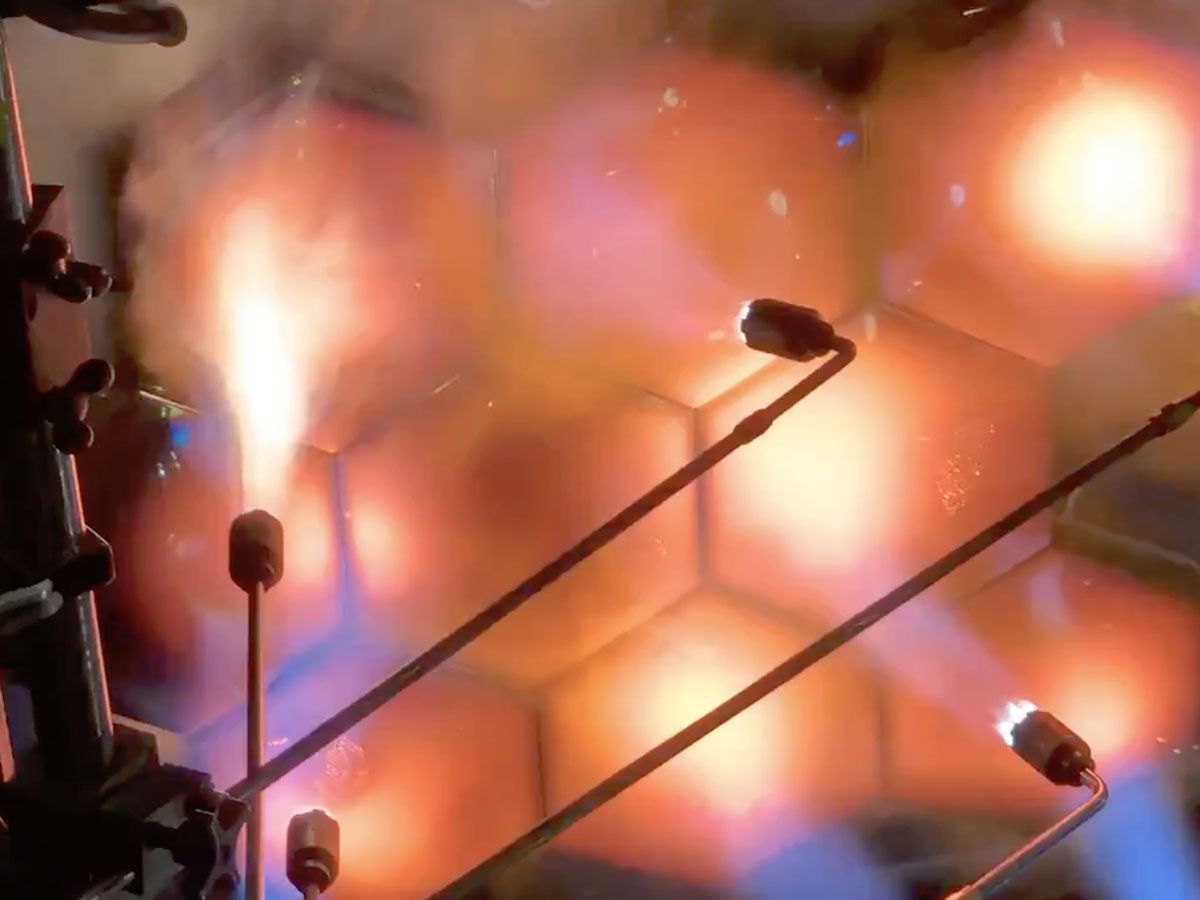

Many different ideas have been tested, from tilting and overlapping the tiles to stitching them together or using a ball-and-socket fastener system. The flexibility offered by the wiring connecting the tiles could potentially dampen vibrations and help maintain their position.

A flexible ceramic fiber mat, sandwiched between the tile and the spacecraft's stainless steel, has been implemented to address tile detachment issues. This, along with other techniques such as tapered holes, anchor nuts, and ceramic putty, are being explored to secure the tiles effectively.

Monitoring and Ensuring the Safety of Starship

Given Starship's complex geometry, simulations and tests are indispensable in ensuring its thermal protection. The spacecraft's large size offers certain advantages in reentry aerodynamics compared to smaller vehicles. However, potential heat shield damage during ascent is a concern that needs to be addressed. Instrumentation or cameras could be employed to monitor the surface, providing valuable data for further refinement of the heat shield design.

It's also worth noting that the FAA's environmental review process has occasionally hindered progress, adding another layer of complexity to the ongoing development work. Nonetheless, the SpaceX team remains undeterred, driven by their grand vision of interplanetary travel.

The road to a reliable heat shield is paved with numerous challenges and a relentless pursuit of innovation. It's a testament to SpaceX's commitment to its mission and a fascinating insight into the rigors of spacecraft design.

Source: TechSpaceX / ALPHATECH / ScottManley